Entrepreneur's Delight

A collection of write-ups from writers/authors willing to write on Entrepreneurship, Business, Corporate Leadership & Management.

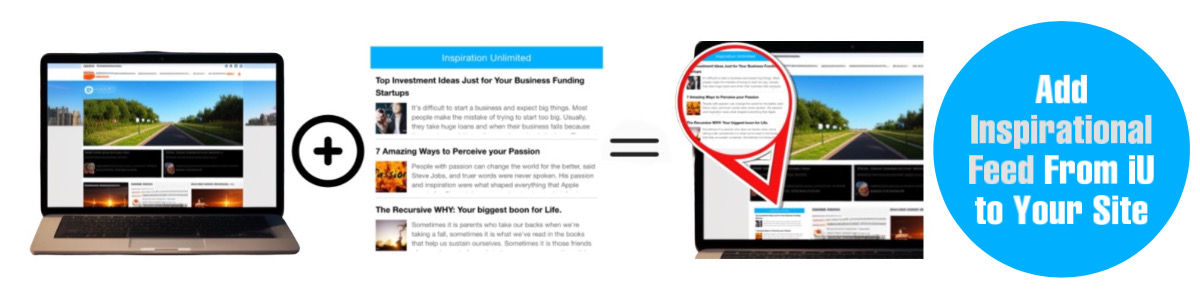

Ad

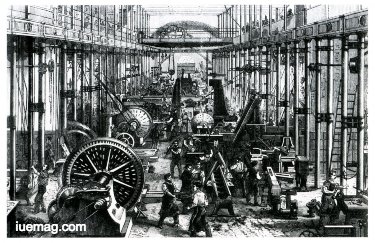

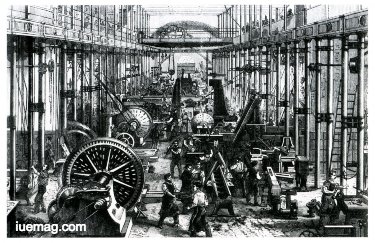

The New Era Of Industrialisation Inspires Progress And Growth

Growth always lead to new opportunities and developments that are unfathomed and unforeseen. Some such results have been seen after Industrial Revolution of last era. The new era has hence dawned, drawing some inspiring developments

Today fourth industrial revolution has changed the whole economy, job opportunities and standard of living. This change was named as "smart factory" and now called "Industry 4.0". There is no field which remained unaffected by future technologies. Rapid changes are taking place in all sectors. New technologies have entered the market, like internet through which connectivity and communication have become comfortable. Other technological development like digitalization, urbanization, and artificial intelligence has made the world very small and brought everyone nearer. Let's discuss in detail about the technical development that has taken place in the industrial area:

Computerization: It has brought drastic changes in the industrial sector. It helps to maintain extensive data efficiently. It created many job opportunities for highly skilled workers, but on the other hand, many employees lost their jobs as they were not updated with new technology. It also helped in increasing productivity efficiently as data was appropriately organized. Duplication of work reduced which increased productivity. Communication between different levels became more comfortable and systematic. The significant change which took place was the replacement of human resource with the computer. Machines replaced Workforce. The productivity of industries increased. When we talk about computerization, we should also understand the concept of Artificial Intelligence. It means developing a computer system which works as human intelligence.

Industrial Manufacturing: Technological development brought changes in industrial manufacturing. The process has become more streamlined and straightforward, duplication of tasks, damages, defects are reduced which reduced cost, waste and increased productivity. Through the use of machinery, products were produced faster. It efficiently fulfilled the demand of consumers which in turn increased supply. It has become easy to provide customer support to consumers as the online facility is available. As defects and damages reduced the quality of the product was improved, so this also helps in meeting customer demand. In industrial areas robots are used to do the repetitive or monotonous task. Cloud computing technology is being used to maintain extensive data systematically, and it can be shared easily with stakeholders, employees, consumers, etc.

Industrial Manufacturing: Technological development brought changes in industrial manufacturing. The process has become more streamlined and straightforward, duplication of tasks, damages, defects are reduced which reduced cost, waste and increased productivity. Through the use of machinery, products were produced faster. It efficiently fulfilled the demand of consumers which in turn increased supply. It has become easy to provide customer support to consumers as the online facility is available. As defects and damages reduced the quality of the product was improved, so this also helps in meeting customer demand. In industrial areas robots are used to do the repetitive or monotonous task. Cloud computing technology is being used to maintain extensive data systematically, and it can be shared easily with stakeholders, employees, consumers, etc.

Filters and Cartridges: Many industries are using filters and cartridges. To remove unwanted particles from the products, these are used. This filtering system has helped and improved manufacturing system of many industries. It has improved the quality of the product; mostly it is used in chemical, automobile, oil and gas, water filtration.

3-D Printing: It is a technique used by manufacturing industries to produce the intricate design. It creates solid objects from digital models. This is also changing the designs thinking of manufacturers. This technique gives the higher return and helps manufacturers in producing complex design efficiently. It saves time and cost for manufacturers.

Cloud Computing: This is a technique practiced by industries to create the network of the internet at different points so that the data can be easily transferred from one location to another. In manufacturing industries, all the processes are interlinked with each other, so information needs to be moved from one point to other. This technique helps in doing so; this increases speed and efficiency of production.

Automation: It means introducing such machinery which performs all the task automatically only monitoring is required to control the process. Machines and equipment used in industries are appropriately interconnected with each other. They know what to do next and how to start the process. Methods are flexible and understand the customers' needs adequately. It reduces the production cost and increases output.

Privacy and Security: If such changes are taking place, then it should also be kept in mind that our data, methods, and processes are not being hacked. Proper security should be implemented to protect information. To sum up, changes keep on taking place in industry continuously. The industry should adopt changes themselves and update their employees to improve productivity by increasing the efficiency to reduce cost and to increase output and profit. Technological development doesn't mean that workforce is not required; it implies human should update their knowledge and skills continue to make use of these technologies appropriately.

Computerization: It has brought drastic changes in the industrial sector. It helps to maintain extensive data efficiently. It created many job opportunities for highly skilled workers, but on the other hand, many employees lost their jobs as they were not updated with new technology. It also helped in increasing productivity efficiently as data was appropriately organized. Duplication of work reduced which increased productivity. Communication between different levels became more comfortable and systematic. The significant change which took place was the replacement of human resource with the computer. Machines replaced Workforce. The productivity of industries increased. When we talk about computerization, we should also understand the concept of Artificial Intelligence. It means developing a computer system which works as human intelligence.

Industrial Manufacturing: Technological development brought changes in industrial manufacturing. The process has become more streamlined and straightforward, duplication of tasks, damages, defects are reduced which reduced cost, waste and increased productivity. Through the use of machinery, products were produced faster. It efficiently fulfilled the demand of consumers which in turn increased supply. It has become easy to provide customer support to consumers as the online facility is available. As defects and damages reduced the quality of the product was improved, so this also helps in meeting customer demand. In industrial areas robots are used to do the repetitive or monotonous task. Cloud computing technology is being used to maintain extensive data systematically, and it can be shared easily with stakeholders, employees, consumers, etc.

Industrial Manufacturing: Technological development brought changes in industrial manufacturing. The process has become more streamlined and straightforward, duplication of tasks, damages, defects are reduced which reduced cost, waste and increased productivity. Through the use of machinery, products were produced faster. It efficiently fulfilled the demand of consumers which in turn increased supply. It has become easy to provide customer support to consumers as the online facility is available. As defects and damages reduced the quality of the product was improved, so this also helps in meeting customer demand. In industrial areas robots are used to do the repetitive or monotonous task. Cloud computing technology is being used to maintain extensive data systematically, and it can be shared easily with stakeholders, employees, consumers, etc.Filters and Cartridges: Many industries are using filters and cartridges. To remove unwanted particles from the products, these are used. This filtering system has helped and improved manufacturing system of many industries. It has improved the quality of the product; mostly it is used in chemical, automobile, oil and gas, water filtration.

3-D Printing: It is a technique used by manufacturing industries to produce the intricate design. It creates solid objects from digital models. This is also changing the designs thinking of manufacturers. This technique gives the higher return and helps manufacturers in producing complex design efficiently. It saves time and cost for manufacturers.

Cloud Computing: This is a technique practiced by industries to create the network of the internet at different points so that the data can be easily transferred from one location to another. In manufacturing industries, all the processes are interlinked with each other, so information needs to be moved from one point to other. This technique helps in doing so; this increases speed and efficiency of production.

Get the Latest & Recommended articles in your Inbox

Automation: It means introducing such machinery which performs all the task automatically only monitoring is required to control the process. Machines and equipment used in industries are appropriately interconnected with each other. They know what to do next and how to start the process. Methods are flexible and understand the customers' needs adequately. It reduces the production cost and increases output.

Privacy and Security: If such changes are taking place, then it should also be kept in mind that our data, methods, and processes are not being hacked. Proper security should be implemented to protect information. To sum up, changes keep on taking place in industry continuously. The industry should adopt changes themselves and update their employees to improve productivity by increasing the efficiency to reduce cost and to increase output and profit. Technological development doesn't mean that workforce is not required; it implies human should update their knowledge and skills continue to make use of these technologies appropriately.

Copyrights © 2024 Inspiration Unlimited eMagazine

Any facts, figures or references stated here are made by the author & don't reflect the endorsement of iU at all times unless otherwise drafted by official staff at iU. This article was first published here on 2nd April 2018.