The Laser Head: Powering Precision in Various Industries

In the modern age of precision manufacturing and cutting-edge technology. The laser head stands as an unsung hero, playing a pivotal role in a multitude of industries. From the intricacies of laser-cutting machines to the intricacies of medical devices.

In the modern age of precision manufacturing and cutting-edge technology. The laser head stands as an unsung hero, playing a pivotal role in a multitude of industries. From the intricacies of laser-cutting machines to the intricacies of medical devices. The laser head is at the forefront of ensuring precision and accuracy. In this comprehensive guide to thunderlaser, we will embark on a journey to explore the world. Understanding their functions, applications, and the vital role they play. Powering precision in various industries in this digital era.

Table of Contents

1. Introduction: The Unsung Hero of Precision

Shedding light on the crucial role of laser heads in modern industries.

2. The Basics of Laser Heads

Unpacking the fundamental components and principles behind laser head technology.

3. How Laser Heads Work: A Glimpse into Precision

Delving into the inner workings of laser heads and demystifying their operation.

4. Applications Across Industries

Discovering the wide-ranging sectors where laser heads are instrumental.

5. Laser Cutting and Engraving: A Closer Look

Exploring how laser heads have transformed the world of cutting and engraving.

6. Medical Devices and Healthcare: Precision at the Forefront

Understanding the critical role of laser heads in medical and healthcare equipment.

7. 3D Printing and Additive Manufacturing: Shaping the Future

Examining the innovative use of laser heads in 3D printing and additive manufacturing.

8. Laser Marking and Etching: Leaving a Lasting Impression

Exploring how laser heads create permanent marks on various materials.

9. Scientific Research and Laboratories: Advancing Precision

Investigating the role of laser heads in scientific experiments and laboratory equipment.

10. Automotive and Aerospace: Precision Engineering

Understanding how laser heads contribute to the precision engineering of vehicles and planes.

11. Choosing the Right Laser Head: Factors to Consider

A practical guide to help you select the ideal laser head for your specific applications.

12. Maintenance and Care: Ensuring Longevity

Tips and best practices for the upkeep of laser heads. That ensures their optimal performance.

13. Laser Safety: Protecting Vision and Equipment

A crucial discussion on safety measures when working with laser heads.

14. Conclusion: A World of Precision Powered by Laser Heads

Summing up the key takeaways and the indispensable role. For laser heads in modern industries.

Introduction: The Unsung Hero of Precision

Precision is the cornerstone of countless industries, from manufacturing and healthcare. As well as research and engineering. In this pursuit of exactness, there exists a silent champion, working behind. It's a component that might not be as recognized as the laser machines. It's a part of it but its role in ensuring precision cannot be overstated.

Precision is the cornerstone of countless industries, from manufacturing and healthcare. As well as research and engineering. In this pursuit of exactness, there exists a silent champion, working behind. It's a component that might not be as recognized as the laser machines. It's a part of it but its role in ensuring precision cannot be overstated.The laser head is often described as the heart of laser-based machinery. Dandles directs the laser beam with unmatched accuracy and consistency. It plays a crucial role in shaping our world. From the precise cuts of industrial materials to the intricate engravings.

This article serves as a window into the world of laser heads click here. Illuminating their inner workings, applications across industries, and the factors. Consider when choosing the right one for specific tasks. We'll explore how laser heads have revolutionized various sectors, enhancing precision and efficiency.

As we embark on this journey, you'll come to appreciate the invaluable contributions. The laser head and understand why it deserves its place as the unsung hero of precision. So, let's delve into the intricate world of laser heads. Unveil the precision they bring to various industries.

The Basics of Laser Heads

To appreciate the capabilities and significance of laser heads, we must start with the basics. These components serve as the bridge between a laser source and the material.

A typical laser head comprises several key elements, including a collimator, a focusing lens, and sometimes a mirror or prism. The collimator's role is to take the laser beam from the source and make it parallel, ensuring that it maintains its focus over long distances.

The focusing lens plays a critical role in converging the laser beam onto the target, enabling precise cutting, marking, or engraving. The laser source, whether it's a solid-state laser, a fiber laser, or a carbon dioxide (CO2) laser, emits a high-intensity beam of light. This beam passes through the collimator, aligning the light waves and making them parallel.

The focusing lens plays a critical role in converging the laser beam onto the target, enabling precise cutting, marking, or engraving. The laser source, whether it's a solid-state laser, a fiber laser, or a carbon dioxide (CO2) laser, emits a high-intensity beam of light. This beam passes through the collimator, aligning the light waves and making them parallel.From the collimator, the beam travels through the focusing lens, allowing the laser head to control the diameter and focal point of the beam. This control is crucial for various applications, as different materials and tasks require different beam characteristics.

Some laser heads also incorporate mirrors or prisms to bend the laser beam's path. This bending can be necessary for directing the beam around corners, positioning it in a way that's most efficient for the specific task at hand.

In summary, the laser head's primary function is to manage the laser beam, ensuring it's collimated, focused, and directed with precision. This fundamental role forms the basis for the laser head's diverse applications across a multitude of industries, where precision is paramount.

How Laser Heads Work: A Glimpse into Precision

Delving into the inner workings of laser heads unveils the intricate mechanisms that contribute to their unparalleled precision. At the heart of the operation lies a choreography of carefully orchestrated steps, ensuring the laser head's ability to navigate the complexities of diverse tasks.

The process begins with the activation of the laser source, whether it be a solid-state laser, a fiber laser, or a carbon dioxide (CO2) laser. This source emits a concentrated beam of light, the foundational element that the laser head will manipulate to achieve precision in various applications.

The process begins with the activation of the laser source, whether it be a solid-state laser, a fiber laser, or a carbon dioxide (CO2) laser. This source emits a concentrated beam of light, the foundational element that the laser head will manipulate to achieve precision in various applications.As the laser beam emerges, the collimator steps into action. Its role is to take the diverging beam and transform it into a parallel one. This crucial step ensures that the laser maintains its focus over extended distances, a fundamental requirement for precision tasks.

The focused beam then encounters the focusing lens, a key player in the precision game. This lens converges the laser beam onto the material, allowing for accurate cutting, engraving, or marking. The ability to control the diameter and focal point of the beam is a defining feature of the laser head, enabling adaptability to different materials and tasks.

To further enhance its versatility, some laser heads incorporate mirrors or prisms. These components facilitate the bending of the laser beam's path, a valuable feature when intricate maneuvers are necessary, such as directing the beam around corners.

Demystifying the operation of laser heads brings to light the meticulous coordination of components working seamlessly to deliver precision. This glimpse into their inner workings underscores the sophistication that powers various industries, pushing the boundaries of what's achievable in manufacturing, healthcare, research, and engineering.

Applications Across Industries

Discovering the wide-ranging sectors where laser heads are instrumental opens a vista of innovation and efficiency. In manufacturing, laser heads revolutionize precision cutting and engraving, shaping materials with meticulous accuracy. The healthcare sector benefits from their application in medical devices, ensuring surgical precision and diagnostic accuracy.

Scientific research and laboratories find laser heads indispensable for intricate experiments, advancing the boundaries of knowledge. Automotive and aerospace industries leverage laser heads for precision engineering, contributing to the creation of high-performance vehicles and aircraft.

Scientific research and laboratories find laser heads indispensable for intricate experiments, advancing the boundaries of knowledge. Automotive and aerospace industries leverage laser heads for precision engineering, contributing to the creation of high-performance vehicles and aircraft.Beyond these, laser heads leave a lasting imprint in 3D printing and additive manufacturing, where their precision is pivotal in shaping intricate designs layer by layer. Laser marking and etching find application in branding and personalization, offering a permanent and precise way to leave a mark on various materials.

Laser Cutting and Engraving: A Closer Look

Embarking on an exploration of how laser heads have transformed the world of cutting and engraving reveals a paradigm shift in precision manufacturing. Laser cutting, powered by these sophisticated heads, transcends traditional methods, offering unparalleled accuracy in shaping materials. From intricate patterns in textiles to precise cuts in metals, the adaptability of laser heads in the manufacturing sector is revolutionary.

Simultaneously, laser engraving emerges as an artistic and precise method of leaving indelible marks on various surfaces. Wood, glass, and plastics bear intricate designs with microscopic precision, a feat made possible by the controlled focus and power of laser heads.

Medical Devices and Healthcare: Precision at the Forefront

Delving into the critical role of laser heads in medical and healthcare equipment unveils a realm where precision is paramount. Laser heads emerged as indispensable tools in the creation of medical devices, contributing to breakthroughs in diagnostics and treatment. In surgical applications, laser heads enable unparalleled precision, facilitating minimally invasive procedures with reduced tissue damage.

Their role extends to therapeutic applications, where laser technology assists in precise interventions, from skin treatments to eye surgeries. Imaging technologies, guided by the precision of laser heads, redefine diagnostic accuracy, enhancing patient care. This elucidates the symbiotic relationship between laser heads and advancements in medical technology, showcasing their crucial role in ensuring precision at the forefront of healthcare innovation.

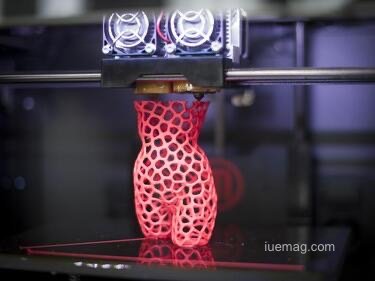

3D Printing and Additive Manufacturing: Shaping the Future

An exploration into the innovative use of laser heads in 3D printing and additive manufacturing reveals a transformative synergy between precision and technology. Laser heads play a pivotal role in shaping the future of manufacturing by guiding the intricate process of layer-by-layer construction. Their precise control over the laser beam ensures the accurate fusion of materials, giving rise to intricate and complex designs.

An exploration into the innovative use of laser heads in 3D printing and additive manufacturing reveals a transformative synergy between precision and technology. Laser heads play a pivotal role in shaping the future of manufacturing by guiding the intricate process of layer-by-layer construction. Their precise control over the laser beam ensures the accurate fusion of materials, giving rise to intricate and complex designs.In additive manufacturing, laser heads facilitate the sintering and melting of powders or polymers, crafting objects with meticulous detail. This method not only enhances production efficiency but also opens avenues for customization and complexity previously unattainable. In today's era, laser heads usher in a new era of manufacturing possibilities, highlighting their integral role in the evolution of 3D printing and additive manufacturing.

Laser Marking and Etching: Leaving a Lasting Impression

A closer examination of laser marking and etching unveils a world where precision meets permanence. Laser heads, the unsung architects of indelible marks, play a transformative role in leaving lasting impressions on various materials. Laser marking, guided by the precision of these heads, offers a methodical and permanent way to imprint logos, serial numbers, or intricate designs on metals, plastics, and even ceramics.

In the artistry of laser etching, surfaces come to life with detailed, permanent patterns. Whether it's the personalization of consumer goods or the traceability of industrial components, laser heads excel in creating enduring marks with micron-level precision.

Scientific Research and Laboratories: Advancing Precision

An in-depth investigation into the role of laser heads in scientific experiments and laboratory equipment reveals a realm where precision is not just a necessity but a catalyst for groundbreaking discoveries. Laser heads stand as indispensable tools in laboratories, advancing the precision required for experiments across diverse scientific disciplines.

In spectroscopy, laser heads enable the precise analysis of molecular structures, unraveling the secrets of matter. Their role extends to microscopy, where laser precision enhances imaging resolution, unlocking new dimensions in cellular exploration. Additionally, laser heads play a pivotal role in the creation and calibration of laboratory equipment, ensuring the accuracy of measurements and experiments.

Laser heads serve as the silent architects of precision in the scientific domain, contributing to the meticulous pursuit of knowledge and pushing the boundaries of what can be achieved in laboratories around the world.

Automotive and Aerospace: Precision Engineering

Diving into the synergy between laser heads and precision engineering in the realms of automotive and aerospace unveils a landscape where minute details make monumental differences. Laser heads emerge as integral components in the manufacturing processes of vehicles and aircraft, contributing to unparalleled precision.

Diving into the synergy between laser heads and precision engineering in the realms of automotive and aerospace unveils a landscape where minute details make monumental differences. Laser heads emerge as integral components in the manufacturing processes of vehicles and aircraft, contributing to unparalleled precision.In automotive applications, laser heads facilitate precision cutting and welding of components, ensuring the structural integrity and accuracy of intricate designs. This precision is not limited to assembly; laser heads play a role in marking and etching, contributing to traceability and branding.

Meanwhile, in the aerospace industry, laser heads are instrumental in crafting lightweight and aerodynamic components. Their precision is indispensable in intricate tasks such as drilling tiny holes or shaping delicate structures.

Choosing the Right Laser Head: Factors to Consider

Navigating the diverse landscape of laser heads requires a nuanced understanding of the factors that shape their efficacy in various applications. This section serves as a practical guide, offering insights to aid in selecting the ideal laser head for specific tasks.

Key considerations include the type of laser source — whether solid-state, fiber, or CO2 — each with its distinct characteristics. Understanding power requirements, focal lengths, and beam diameters becomes crucial for achieving optimal results. Application-specific factors such as material type, thickness, and desired precision guide the selection process.

Maintenance and Care: Ensuring Longevity

Unlocking the full potential of laser heads extends beyond their initial installation; it hinges on a regimen of meticulous maintenance and care. This section provides indispensable tips and best practices for preserving the longevity of laser heads, guaranteeing sustained optimal performance.

Routine cleaning procedures, focusing on critical components like lenses and mirrors, form the foundation of effective maintenance. Calibration checks, aligned with manufacturer guidelines, become a proactive measure to retain precision. Temperature and humidity control in the operational environment further contribute to longevity.

Laser Safety: Protecting Vision and Equipment

Engaging with laser heads necessitates a paramount commitment to safety. This section initiates a crucial discussion on comprehensive safety measures imperative for those working with laser heads. Emphasizing the significance of protective eyewear, it addresses the critical aspect of safeguarding vision from the intense beams emitted by these precision tools.

Engaging with laser heads necessitates a paramount commitment to safety. This section initiates a crucial discussion on comprehensive safety measures imperative for those working with laser heads. Emphasizing the significance of protective eyewear, it addresses the critical aspect of safeguarding vision from the intense beams emitted by these precision tools.Furthermore, the discussion extends to protective measures for equipment, ensuring the longevity and functionality of laser heads. Proper shielding and containment protocols mitigate the risks associated with laser operation, fostering a secure working environment.

Conclusion: A World of Precision Powered by Laser Heads

In the intricate dance between technology and precision, laser heads emerge as unsung heroes, orchestrating a symphony of accuracy across diverse industries. As we conclude this exploration into their world, it becomes evident that laser heads are not mere components; they are architects of precision, shaping a world where intricacy meets innovation.Summing up, the key takeaways echo the indispensable role of laser heads in modern industries. From manufacturing and healthcare to research, their ability to guide laser beams with unmatched precision redefines what's achievable. These silent champions contribute to the creation of intricate designs, the advancement of scientific knowledge, and the development of cutting-edge technologies.

Copyrights © 2025 Inspiration Unlimited - iU - Online Global Positivity Media

Any facts, figures or references stated here are made by the author & don't reflect the endorsement of iU at all times unless otherwise drafted by official staff at iU. A part [small/large] could be AI generated content at times and it's inevitable today. If you have a feedback particularly with regards to that, feel free to let us know. This article was first published here on 18th December 2023.

Overthinking? Uninspired? Brain Fogged?

Let's Reset That! Try iU's Positivity Chat NOW!

All chats are end-to-end encrypted by WhatsApp and won't be shared anywhere [won't be stored either].