How Does an Electric Drive Hydraulic Pump Function?

An electric motor drives hydraulic pumps, which transform electrical energy into fluid pressure. For all hydraulic drives, they are required. Hydraulic fluid then delivers the fluid pressure to cylinders, actuators, and hydraulic motors at the needed pressure and volume. Hydraulic pumps, in comparison to hydraulic motors, work at higher speeds and pressures. While some gate drives use reversible pumps, most use a unidirectional pump with a directional control valve like sun cbbg-ljn to reverse the actuators' activity.

An electric motor drives hydraulic pumps, which transform electrical energy into fluid pressure. For all hydraulic drives, they are required. Hydraulic fluid then delivers the fluid pressure to cylinders, actuators, and hydraulic motors at the needed pressure and volume. Hydraulic pumps, in comparison to hydraulic motors, work at higher speeds and pressures. While some gate drives use reversible pumps, most use a unidirectional pump with a directional control valve like sun cbbg-ljn to reverse the actuators' activity.Hydraulic pumps, like hydraulic motors, are divided into three categories: gear, piston, and vane. It is usual and encouraged within the USACE to include redundant hydraulic pumps and electric drive motors.

Each pump is identical and sized to drive the hydraulic system's required loads. With each gate operation, the pumps are cycled. The hydraulic pump and electric motor are now installed as part of an HPU package in the vast majority of USACE gate drives. Pumps can be fixed, positive displacement, or variable displacement.

The volume of fixed displacement pumps is governed by the pump's capacity and the electric motor's speed. Internal and external gear pumps, axial and radial piston pumps, screw pumps, and vane pumps are examples of fixed displacement pumps. Variable volume pumps are typically vane pumps that are designed and built as variable flow or displacement pumps.

The gear pump is the simplest and most durable positive displacement pump, with only two working elements. Gear pumps offer a high fluid contamination tolerance, excellent overall efficiency, and are reasonably silent. Gear pumps are likely to be a better alternative if fluid contamination is a constant worry. The flow rate and speed characteristics of these pumps are linear within their efficiency ranges, despite the fact that they have a fixed volume at a given speed (in rpm). Driving a reversible gear pump with a variable speed electric motor, motor, can give speed and direction control to a drive system. This is appropriate for HPUs with integrated graphics. Gear pumps are usually limited to working pressures of less than 24 MPa (3500 psi).

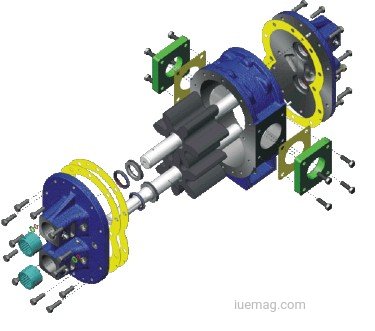

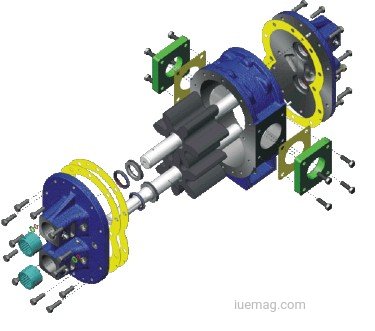

Gate drives frequently employ the piston pump. It boasts the highest volumetric efficiency, overall efficiency, output pressures, and life expectancy of any device. This type of pump is available in variable displacement models with a wide range of pressure and capacity control mechanisms. To reduce noise and extend pump life, the electric drive motor is frequently limited to 900–1200 rpm. Piston pumps are typically limited to a maximum pressure of 42 MPa (6000 psi), which is more than enough for the majority of gate drives. Axial piston pumps have pistons that are placed parallel to the driving shaft and are utilized for high-pressure and high-volume applications. Click here to know more.

Gate drives frequently employ the piston pump. It boasts the highest volumetric efficiency, overall efficiency, output pressures, and life expectancy of any device. This type of pump is available in variable displacement models with a wide range of pressure and capacity control mechanisms. To reduce noise and extend pump life, the electric drive motor is frequently limited to 900–1200 rpm. Piston pumps are typically limited to a maximum pressure of 42 MPa (6000 psi), which is more than enough for the majority of gate drives. Axial piston pumps have pistons that are placed parallel to the driving shaft and are utilized for high-pressure and high-volume applications. Click here to know more.

The swashplate and bent axis designs are the two most common forms of axial piston pumps. The bent axis design is thought to be quieter, vibration-free, and wear-resistant than the swash plate design.

Swashplate pumps can be designed to drive a separate pilot pressure pump from a shaft extension, while bent axis pumps will require a separate electric motor and pump arrangement for pilot pressure. Radial rolling piston pumps have a basic construction and are exceedingly reliable. Around a drive shaft, the pistons extend in a radial manner. Solenoid controllers for up to five discrete working speeds are common in standard designs. To allow for field adaptation, each of the operating speeds has a variable adjustment range ranging from zero to maximum volume capacity.

Companies selling Hydraulic power pack pump units:-

The oil-filled pressure gauge may show the pump's current working pressure, preventing harm from overloading. Hydraulic pump with two speeds. Fuse: used to safeguard the motor and machine from overheating. Internal memory: an internal memory device is configured to indicate usage times and offer maintenance reference data. It is necessary to change the hydraulic oil at least once a year, and R- 32 super special cycle oil should be used. More information can be found on their official website.

We are engaged in offering a wide range of Hydraulic Power Packs due to our technologically advanced manufacturing facility. These packs are created and designed with high-quality raw materials in accordance with industry standards. Our packs are widely used in a variety of industries, including construction and pipeline construction. Furthermore, our entire range is rigorously tested under the watchful eye of quality inspectors to ensure that only high-quality packs arrive at clients' locations on time.

Image 2: Reed T. Warnick, CC BY-SA 3.0, via Wikimedia Commons

The gear pump is the simplest and most durable positive displacement pump, with only two working elements. Gear pumps offer a high fluid contamination tolerance, excellent overall efficiency, and are reasonably silent. Gear pumps are likely to be a better alternative if fluid contamination is a constant worry. The flow rate and speed characteristics of these pumps are linear within their efficiency ranges, despite the fact that they have a fixed volume at a given speed (in rpm). Driving a reversible gear pump with a variable speed electric motor, motor, can give speed and direction control to a drive system. This is appropriate for HPUs with integrated graphics. Gear pumps are usually limited to working pressures of less than 24 MPa (3500 psi).

Gate drives frequently employ the piston pump. It boasts the highest volumetric efficiency, overall efficiency, output pressures, and life expectancy of any device. This type of pump is available in variable displacement models with a wide range of pressure and capacity control mechanisms. To reduce noise and extend pump life, the electric drive motor is frequently limited to 900–1200 rpm. Piston pumps are typically limited to a maximum pressure of 42 MPa (6000 psi), which is more than enough for the majority of gate drives. Axial piston pumps have pistons that are placed parallel to the driving shaft and are utilized for high-pressure and high-volume applications. Click here to know more.

Gate drives frequently employ the piston pump. It boasts the highest volumetric efficiency, overall efficiency, output pressures, and life expectancy of any device. This type of pump is available in variable displacement models with a wide range of pressure and capacity control mechanisms. To reduce noise and extend pump life, the electric drive motor is frequently limited to 900–1200 rpm. Piston pumps are typically limited to a maximum pressure of 42 MPa (6000 psi), which is more than enough for the majority of gate drives. Axial piston pumps have pistons that are placed parallel to the driving shaft and are utilized for high-pressure and high-volume applications. Click here to know more.The swashplate and bent axis designs are the two most common forms of axial piston pumps. The bent axis design is thought to be quieter, vibration-free, and wear-resistant than the swash plate design.

Swashplate pumps can be designed to drive a separate pilot pressure pump from a shaft extension, while bent axis pumps will require a separate electric motor and pump arrangement for pilot pressure. Radial rolling piston pumps have a basic construction and are exceedingly reliable. Around a drive shaft, the pistons extend in a radial manner. Solenoid controllers for up to five discrete working speeds are common in standard designs. To allow for field adaptation, each of the operating speeds has a variable adjustment range ranging from zero to maximum volume capacity.

Companies selling Hydraulic power pack pump units:-

Riverlake

The oil-filled pressure gauge may show the pump's current working pressure, preventing harm from overloading. Hydraulic pump with two speeds. Fuse: used to safeguard the motor and machine from overheating. Internal memory: an internal memory device is configured to indicate usage times and offer maintenance reference data. It is necessary to change the hydraulic oil at least once a year, and R- 32 super special cycle oil should be used. More information can be found on their official website.

Indiamart

We are engaged in offering a wide range of Hydraulic Power Packs due to our technologically advanced manufacturing facility. These packs are created and designed with high-quality raw materials in accordance with industry standards. Our packs are widely used in a variety of industries, including construction and pipeline construction. Furthermore, our entire range is rigorously tested under the watchful eye of quality inspectors to ensure that only high-quality packs arrive at clients' locations on time.

Features:

- Low electricity usage

- Installation is simple, and the product has a long life expectancy.

- Additional details include:

- Hydraulic power packs that are tailored to the customer's specifications are available.

- Services for converting old circuits to new ones.

- Parts are in short supply.

Image 2: Reed T. Warnick, CC BY-SA 3.0, via Wikimedia Commons

Copyrights © 2026 Inspiration Unlimited - iU - Online Global Positivity Media

Any facts, figures or references stated here are made by the author & don't reflect the endorsement of iU at all times unless otherwise drafted by official staff at iU. A part [small/large] could be AI generated content at times and it's inevitable today. If you have a feedback particularly with regards to that, feel free to let us know. This article was first published here on 22nd February 2022.

Overthinking? Uninspired? Brain Fogged?

Let's Reset That! Try iU's Positivity Chat NOW!

All chats are end-to-end encrypted by WhatsApp and won't be shared anywhere [won't be stored either].